Special Work Steps when Producing a KAFO with a NEURO MATIC

Special Work Steps when Producing a KAFO with a NEURO MATIC

In this online tutorial, you can find information on special work steps that you need to consider when producing an orthosis with the automatic system knee joint NEURO MATIC. This includes the placement of dummies, the particularities of the reinforcement process and the handling of the cable cover conduit.

Here you can find step-by-step instructions for the assembly of a NEURO MATIC system knee joint.

-

Preparing the Reinforcement

-

Step 1/7

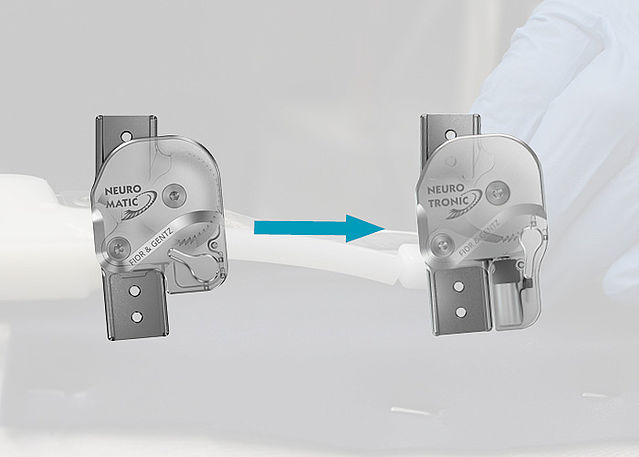

Cut the assembly/lamination dummy along the marking to achieve a visually appealing result. If you should like to keep the option for a conversion into a NEURO TRONIC, do not shorten the assembly/lamination dummy!

Step 2/7

Mount the system string on the positive cast.

Step 3/7

Assembly/Lamination Dummy for the System Knee Joint

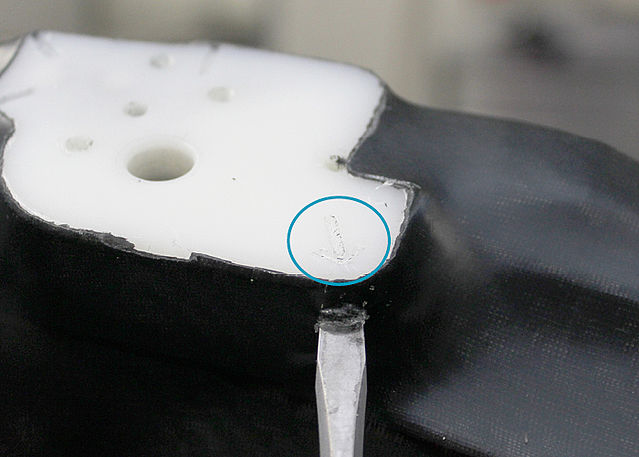

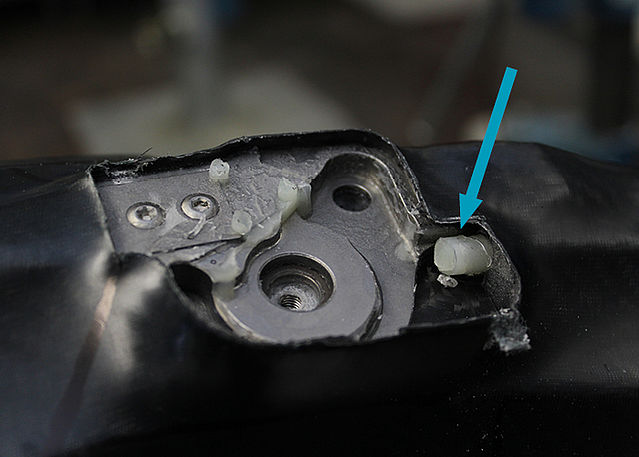

The deep bore (blue arrow) is the retainer for the cable cover conduit of the NEURO MATIC system knee joint.

The small bore (blue circle) is the connecting point for the solenoid connection cable of the NEURO TRONIC system knee joint.Step 4/7

Slide one end of the cable cover conduit into the assembly/lamination dummy as far as it will go.

Important! The deep bore in the assembly/lamination dummy is only needed for the NEURO MATIC system knee joint and not for the NEURO TRONIC.Step 5/7

Adhere the lamination dummy for the cable cover guidance to the other end of the cable cover conduit with medium-viscous fast-acting adhesive.

Step 6/7

Optional:

If you should like to keep the option of a conversion into a NEURO TRONIC, also place the lamination dummy for the solenoid connection cable as well as the lamination dummy for the cable length compensation and use the lamination dummy for the controller either underneath the foil or as a shaping dummy. Here you can find details on the production technique.Step 7/7

Remove the system string. If the positive cast is still wet, insulate it with compression film. Then, pull a PA reinforcement stocking and a PVA film tube over the positive cast. The lamination dummy for the cable cover guidance is now located under the PVA film tube and is thus part of the model.

-

Reinforcing the KAFO

-

Step 1/3

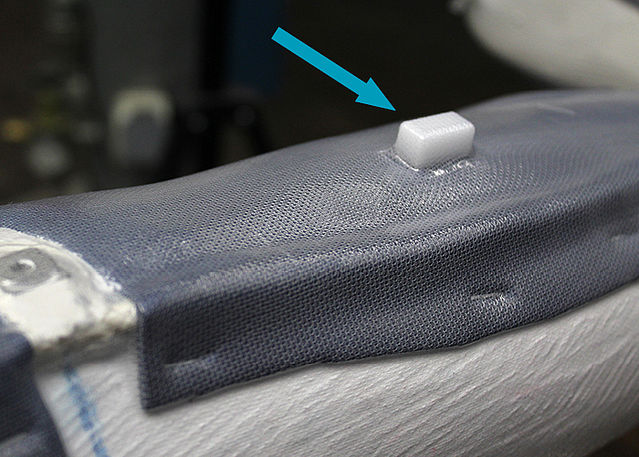

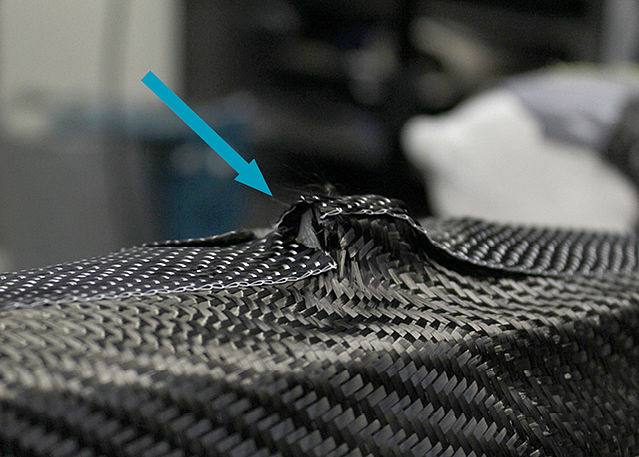

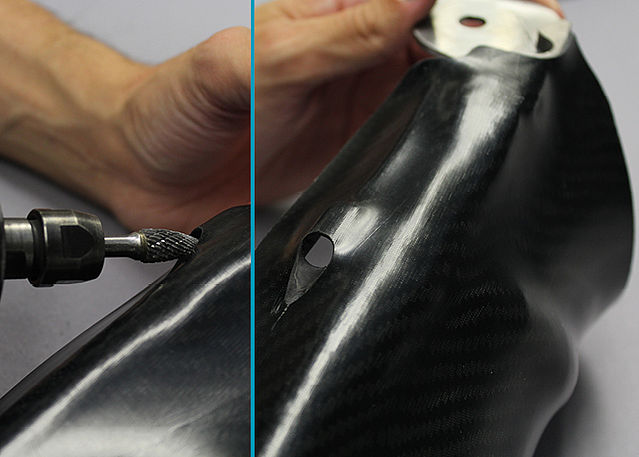

Reinforce the orthosis shells. Make a small incision in the reinforcement layers at the lamination dummy for the cable cover guidance as shown in the picture. The incision exposes the lamination dummy in the direction of the joint retainer. This enables the direct connection of the cable cover conduit to the lamination dummy in a later work step.

Important! The base film must not be cut!Step 2/3

With each new layer of reinforcement, make sure to leave out the area that has been cut. Reinforce up to the point where the system string is mounted.

Step 3/3

Fill the cable cover conduit completely with insulating wax. Mount the system string. Guide the cable cover conduit through the incision to the lamination dummy for the cable cover guidance. Proceed with the reinforcement. Cover both lamination dummies with the last layer.

-

Laminating the KAFO

-

Step 1/2

This production technique is specifically adapted to our epoxy resin and hardener.

Important! Please note the processing instructions and the safety data sheet for our epoxy resin and hardener. Keep to the mixture ratio exactly and mix resin and hardener thoroughly.Step 2/2

Allow the fibres to soak thoroughly when casting and rub out any excess resin. Leave the model overnight (at least 10 hours) under vacuum at room temperature.

Important! Follow the processing instructions for the epoxy resin here as well.

-

Cutting the KAFO

-

Step 1/3

Cut the system joints free. An arrow is milled on the assembly/lamination dummy to indicate where to lever out.

Step 2/3

Saw the orthosis shells and remove them from the model.

Note: the protruding piece of the cable cover conduit is shortened flush in the next step.Step 3/3

The cable cover conduit now ends in the cavity (A) created by the lamination dummy for the cable cover guidance. Cut the protruding cable cover conduit at the system joint flush with a knife (B). Remove the insulating wax from the cable cover conduit.

-

Tempering and Grinding the KAFO

-

Step 1/2

Clean the orthosis shells and remove the PVA film tube. Temper the orthosis shells.

Important! Follow the processing instructions for the epoxy resin here as well.Step 2/2

Grind the orthosis shells. Make an opening for the cable cover conduit with a drillgrinder as shown in the picture.

-

Mounting System Joints

-

Step 1/1

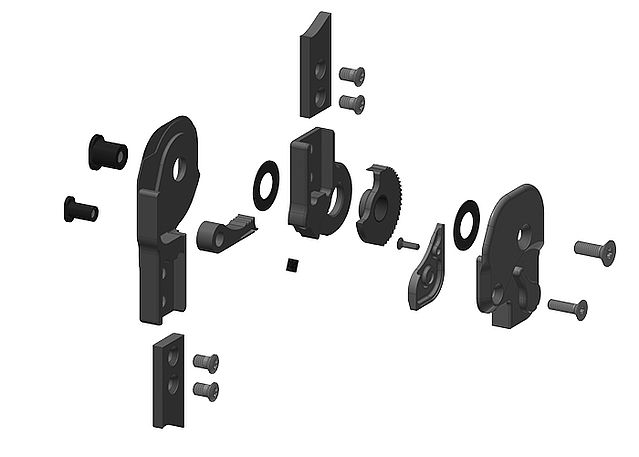

Mount the system joint as described in the instructions for use and the corresponding online tutorial.

Last Update: 24 April 2024