Model Technique

What happens at the model technique?

The model is the basis for the process of Producing the Orthosis.

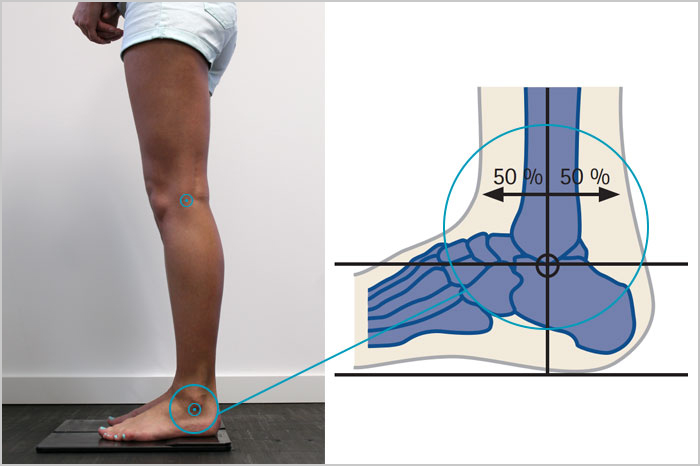

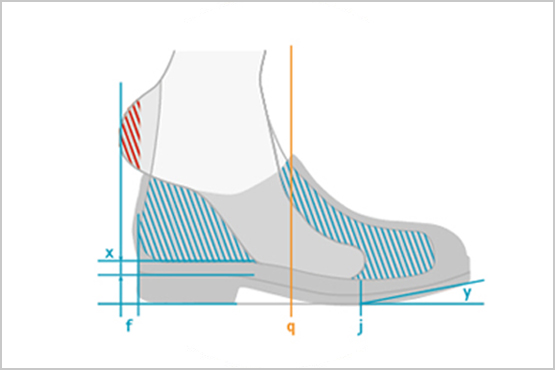

At the model technique, the alignment of the orthosis/the position of the patient is determined (statics). The position and alignment of the system joints as well as the distance between system joints and the patient’s leg or model is determined, too.

Then, the inner orthosis shell is modelled on the surface of the positive cast to gain a perfect fit of the orthosis shells (equivalent to the negative). This is a complex procedure that requires a lot of skill and technical finesse.

In total, the model is based on:

- the form of the patient’s leg (1);

- the treatment goal (2) defined during Planning the Orthosis incl. corrections and compensations and

- from a functional point of view, relevant considerations (regarding statics, positioning and alignment of the axes (3) as well as usage and realisation of the Functional Elements of the Orthosis.

Why do we describe this version of the Model Technique?

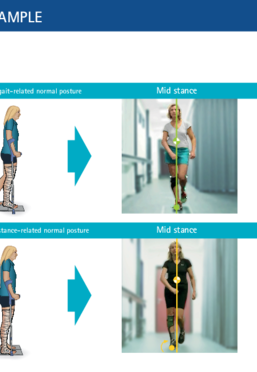

In order to produce a model that forms the ideal compromise between standing and walking, defined lever lengths as well as correctly positioned pivot points are needed, among other things.

The wearing comfort is a basic precondition for the forces, resulting from the ground reaction forces, being able to affect the patient’s leg in a functionally usable way.

The moment of taking the plaster cast is the first moment that can have an impact on achieving the treatment goal. Not only because a well-fitted orthosis is proprioceptively fundamental but also because the position of the model determines the orthosis’ static basic alignment. The plaster cast also determines the position of the dorsiflexion stop and extension stop.

Planning the Orthosis should be done before the model is produced, since all important data (such as e.g. the pitch, possible compensations and the correction potential) have already been collected for this step. This approach enables the orthotist to take a precise plaster cast and to continue working the model accurately afterwards.

As this process is very efficient, the time-consuming production of test shells and test orthoses becomes as obsolete as the necessity of numerous fittings and appointments with the patient.