Joint Assembly System Ankle Joints

Joint Assembly System Ankle Joints

Using NEURO VARIO-SPRING as an Example

This online tutorial shows the joint assembly of the following system ankle joints:

- NEURO CLASSIC

- NEURO VARIO

- NEURO VARIO-CLASSIC

- NEURO VARIO-SPRING

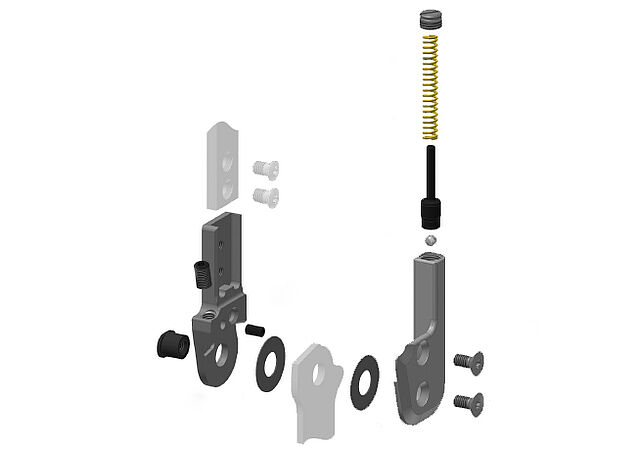

The NEURO VARIO-SPRING system ankle joint is a joint with dorsiflexion assist and provides a pressure spring as well. For the assembly of the 16 and 20mm system joints, you can use the assembly aid for cover plate. You will find more information in the instructions for use.

In addition, the NEURO VARIO-SPRING is, alongside with the NEURO SWING, NEURO VARIO-SWING and NEURO SWING 2, a system ankle joint, which can be connected to the automatic knee joint system NEURO MATIC. Then, a mechanical connection between system knee and system ankle joint controls the locking and unlocking of the system knee joint.

Here, in the online tutorial, you can find the instructions for the assembly of the NEURO MATIC system knee joint in combination with the NEURO VARIO-SPRING system ankle joint.

-

Joint Assembly System Ankle Joints

-

Step 1/15

Clean the system joint. In order to clean the threads in the cover plate, use the Super Clean LOCTITE® 7063 to remove any insulating wax residues.

Note: Mind the safety data sheet when using the Super Clean LOCTITE® 7063.Step 2/15

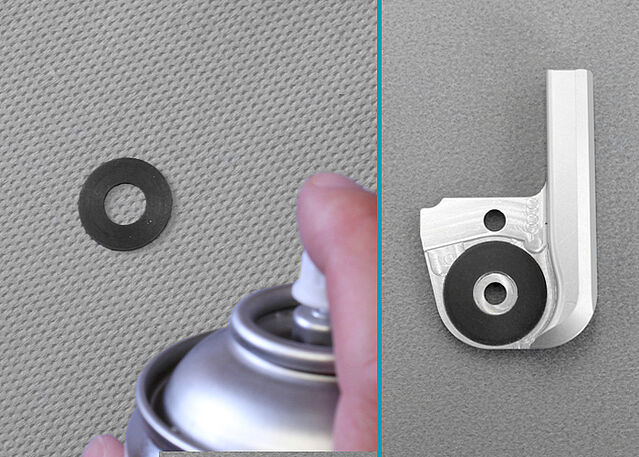

Apply spray adhesive to one side of the first sliding washer and adhere it to the cover plate. Continue by greasing the other side of the sliding washer slightly with orthosis joint grease.

Step 3/15

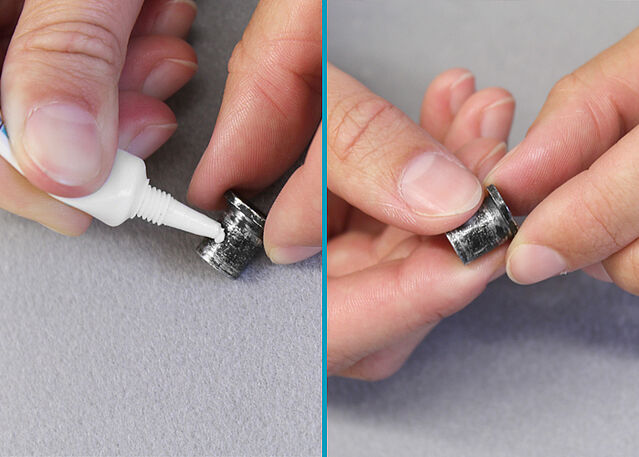

Grease the friction surfaces of the bearing nut slightly with orthosis joint grease.

Step 4/15

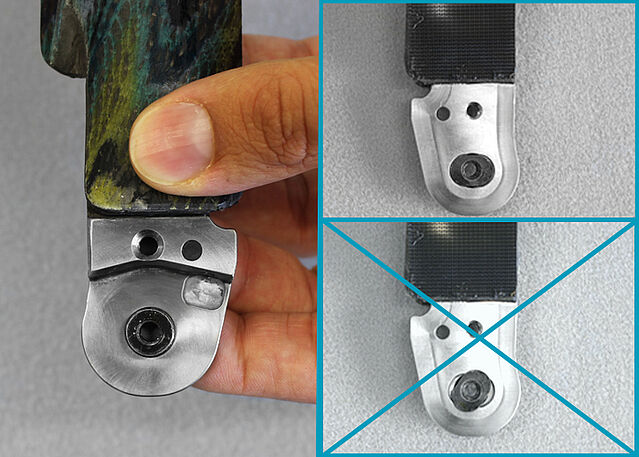

Put the bearing nut into the intended opening of the joint's upper part. Ensure that the bearing nut is in the correct position. Fix it from the backside with one finger.

Step 5/15

In case the sliding bushing fell out in the previous steps, grease it slightly and place it into the bore at the system stirrup again.

Step 6/15

Slightly grease the second sliding washer on both sides with orthosis joint grease.

Step 7/15

Place the second sliding washer onto the joint's upper part and mount the system stirrup while still fixing the bearing nut.

Step 8/15

Mount the cover plate. Turn in the first countersunk flat head screw (axle screw). Continue with the second countersunk head screw using the corresponding torque while still fixing the bearing nut.

Note: You will find the appropriate torque (Nm) on the cover plate of the system joint or in the instructions for use.Step 9/15

If you have damaged the sliding washer during the assembly of the cover plate (you would hear a soft cracking), remove the particles and place a new sliding washer.

Step 10/15

Check if the bearing nut is placed completely in the intended opening.

Step 11/15

Bring the system joint in plantar flexion/dorsiflexion. If the system joint does not move freely (it jams), you need to mount the next thinner sliding washers and repeat all steps starting at the 5th. Check again.

Note: Check if the system joint moves freely before mounting the spring. At a bilateral orthosis, only check one system joint at a time.Step 12/15

Fix the tibial shell and try to move the foot shell in pronation-supination direction. If the system joint runs with lateral play, you need to mount the next thicker sliding washers and repeat all steps starting at the 5th. Check again.

Note: Check if the system joint runs with lateral play before mounting the spring. At a bilateral orthosis, only check one system joint at a time.Step 13/15

Secure both screws with LOCTITE® 243 medium strength and the torque corresponding to the system width. Let the adhesive harden (final strength after approx. 24 hours). Insert the ball, the pin and the spring into the spring duct and turn in the pressure screw as far as possible.

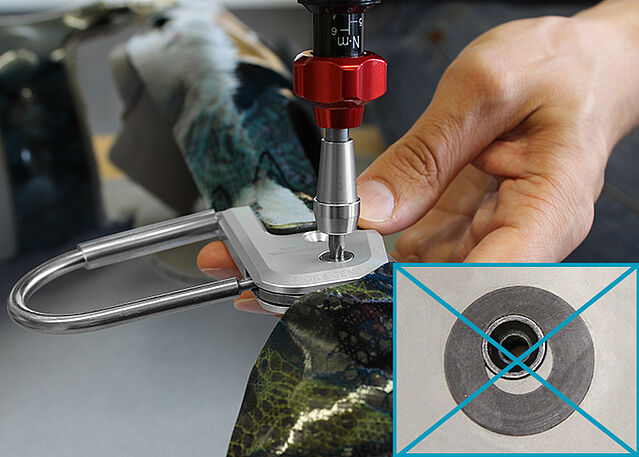

Note: Mind the safety data sheet when using LOCTITE® 243 medium strength.At 16 and 20mm system joints with pressure springs, we recommend using the assembly aid for cover plate.

Note: You will find information about using the assembly aid for cover plate in the instructions for use.Step 14/15

If you have damaged the sliding washer during the assembly of the cover plate (you would hear a soft cracking), remove the particles and place a new sliding washer.

Step 15/15

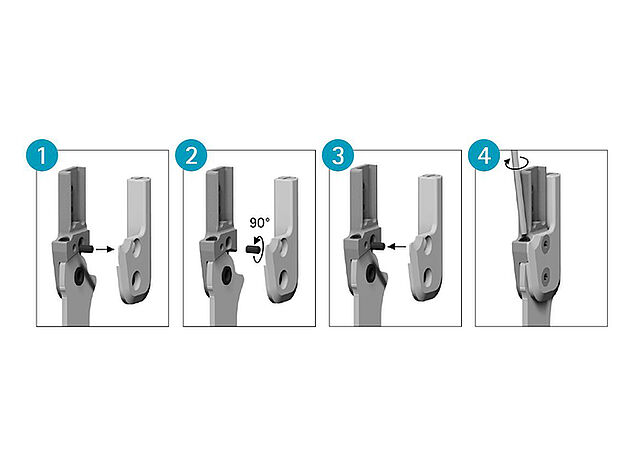

When the adjusting screw turns or loosens, it must be secured again with the securing pin. Please follow the instructions for use.

Last Update: 29 August 2022