Bending System Stirrups/Anchors

Bending System Stirrups/Anchors

System anchors are connecting elements. In the Anchor Lamination/Prepreg Technique and the Joint Lamination/Prepreg Technique, they are embedded into the laminate. When producing a custom-made orthosis, it is necessary to adapt the system stirrups and anchors. Depending on the material, a defined bending radius should be observed during bending in order to ensure stability.

You can find the bending radii for system stirrups and anchors in different materials in the instructions for use.

-

Bending the System Stirrups/Anchors

-

Step 1/12

First, mark the lower edge of the assembly/lamination dummy on the system stirrup. Everything above this line must not be bent, as this area (the joint area) is a part of the system joint later.

Note: When you have acquired a bent system stirrup, you can skip the steps 2 to 4.Step 2/12

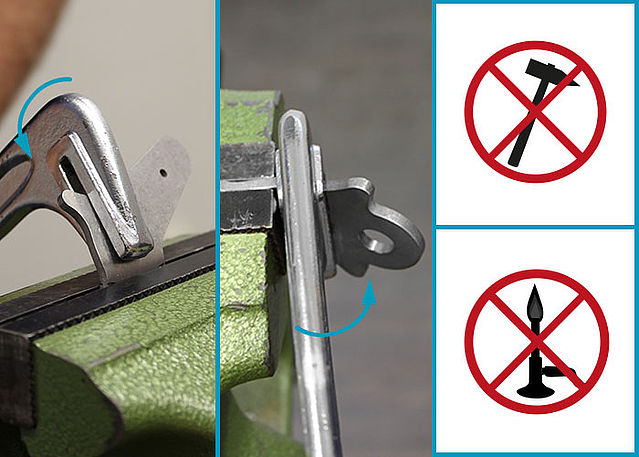

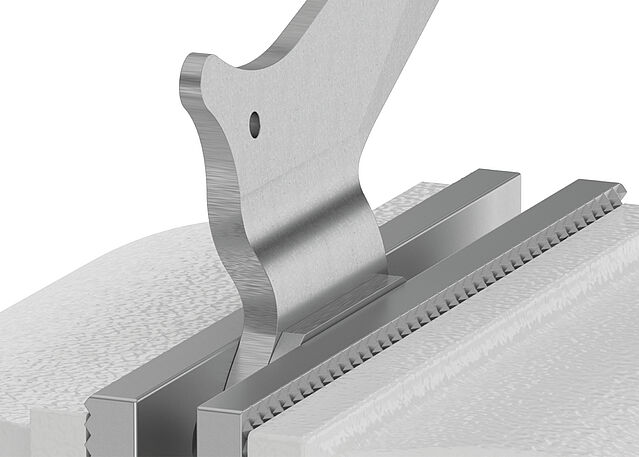

Clamp the system stirrup into a vice with plain jaws to bend it. Pay attention to the marking to avoid a subsequent deformation of the joint areas and to be able to bend very close to the joint.

Note: When you have acquired a bent system stirrup, you can skip the steps 2 to 4.Step 3/12

Adapt the system stirrup to the shape of the model. Bend the system stirrup neck with a bending iron. Only bend in one direction. Do not use a hammer and do not heat the material.

Note: When you have acquired a bent system stirrup, you can skip the steps 2 to 4.Step 4/12

Remove the system stirrup from the vice and check the distance from the system stirrup to the model.

Note: When you have acquired a bent system stirrup, you can skip the steps 2 to 4.Step 5/12

Adapt the system stirrup to the shape of the model. Bend the lower part of the system stirrup with a bending iron. Only bend in one direction.

Check if there is enough space left for the reinforcement layers between system stirrup and model.Step 6/12

Adapt the system stirrup to the shape of the model. Bend the system stirrup foot with a bending iron. Only bend in one direction.

Check if there is enough space left for the reinforcement layers between system stirrup and model.Step 7/12

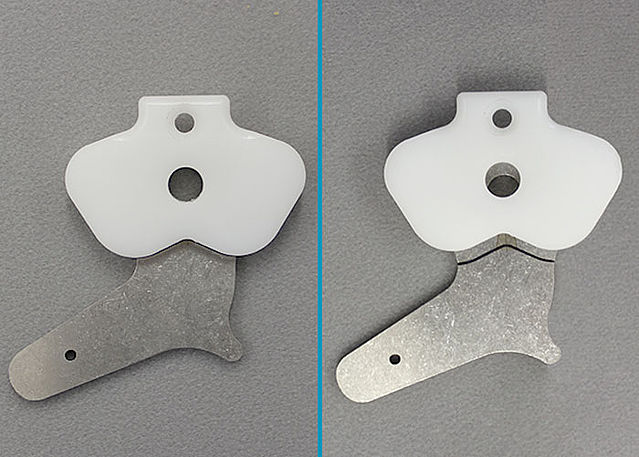

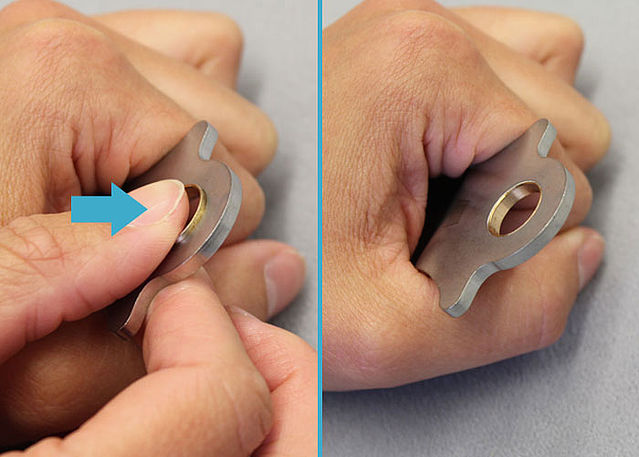

In case the sliding bushing fell out during the bending process, grease it slightly and place it into the bore at the system stirrup again.

Step 8/12

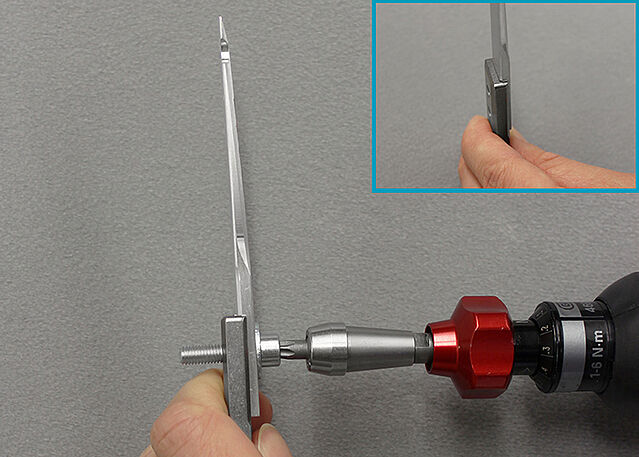

Press the system anchor to the joint’s upper part by using a washer and a screw (or the cover plate pressing aid of the plug + go system joints). To do so, use a torque screwdriver and a torque of 6 Nm. Then, remove washer and screw.

Step 9/12

Fix the system anchor with the screw (farther away from the joint) at the joint's upper part before you begin bending.

Step 10/12

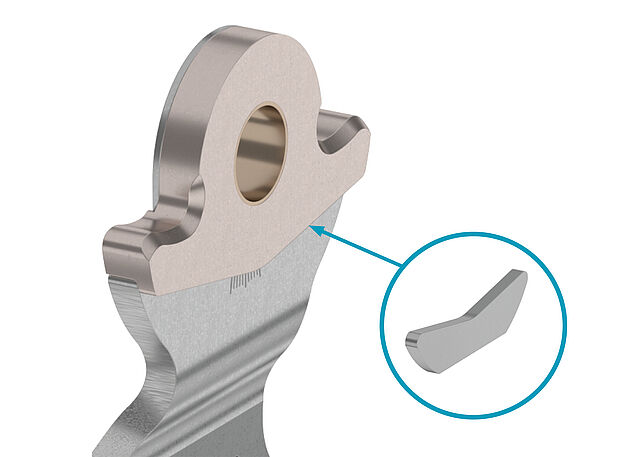

While bending, please consider the applicable bending radii and use a bending iron with round edges.

Note: You will find information on bending radii and the tools to be used in the instructions for use.Step 11/12

Check the distance from system anchor and stirrup to the positive cast. Please make sure to have enough space left for the reinforcing profile and the reinforcement layers in order to avoid later strains to the laminate. Thus, the joint areas stay parallel.

Step 12/12

Grind the system stirrup and the system anchor. Always grind in direction of rolling. Remove all notches from bending and avoid sharp edges.

Note: system ankle joints with dorsiflexion stop, which can be adjusted by filing, should always be mounted in their pre-assembled neutral position without changing the dorsiflexion stop.

-

NEURO SWING 24mm

-

Step 1/3

The clamping aid for system stirrups ensures the correct bending of the system stirrup. The area of the system stirrup’s head and the clamping aid must not be bent. Thus, later damage to the cover plate is prevented.

Note: the work steps for bending the system stirrup can exactly be performed as described at “Bending the System Stirrups/Anchors” in this online tutorial.Step 2/3

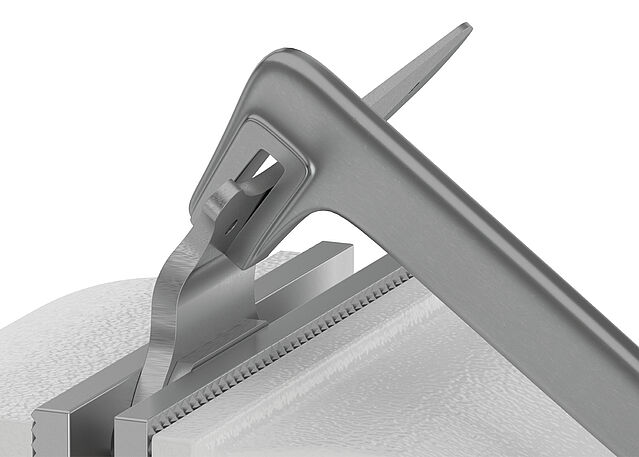

Note the following particularities when bending the system stirrup for the NEURO SWING 24mm:

Place the clamping aid on the system stirrup directly under the system stirrup’s head.

Clamp the clamping aid together with the system stirrup into a vice with plain jaws.Step 3/3

Only bend the area below the clamping aid in order to prevent later damages to the cover plate.

Last Update: 27 March 2024